Electrical equipment is generally designed for a certain economic service life. The concept of simple replacement of electrical equipment in the system either before or after their economic service life, considering it as weak or a potential source of trouble, is now less valid in the present scenario of financial constraints. Reduction of equipment failure improves reliability and effectively extends the life of equipment. Utilities are continuously in search of ways and means other than conventional methods/techniques to assess the condition of equipment in service. This promotes remedial measures to be taken in advance to avoid disastrous upset thereby preventing upset and loss of resources. Today the concept has changed and efforts are being directed to explore new approaches/techniques of monitoring, diagnosis, life assessment and condition evaluation, and possibility of extending the life of assets such as circuit breakers, cables, oil filled equipment, load tap changer etc. Minimization of the service life cycle cost is one of the stated tasks of the electrical power system engineers. The main goal is therefore to reach a cost effective solution for available resources which is captured by the concept of Asset Management. Maintenance is one of the areas where higher effectiveness is sought, and utilities are implementing new strategies for maintenance and management of assets. The pressure to reduce operational and maintenance costs is already being felt and the criteria for Preventive Maintenance is undergoing change.

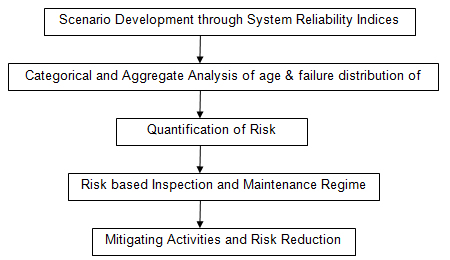

Faster growth influenced by slowing investment and increasing competition among electrical power utilities due to deregulation, the average age of any given asset is increasing. Additionally, growing operating stresses from larger loads and increased fault current levels accelerate asset's physical aging process. This "aging squared" phenomenon has been difficult to measure and analyze, since operating conditions on an asset vary according to its technology, make, model, age, and application. Distribution companies can benefit from strategies to improve reliability and optimize performance of their asset population that consider the units' design, maintenance, and operating characteristics. Quantifying the risks facing a specific asset population will help owners develop appropriate maintenance plans and replacement strategies as well as the budgets needed to support them.Becoming aware of risk, how to measure it and how to use it to establish priorities are important keys to successful maintenance management. The basic premise of risk-based maintenance management is that risk can be quantified and then prioritized. The results of this risk-based focus can be used to establish capital and expense allocations to preventive, predictive and reactive maintenance management decisions. Therefore "Risk Based Maintenance" planning permits the power system engineers to base these tasks using Risk as a foundation for prioritizing and managing the efforts of the inspection and maintenance programs. The flow chart of the Risk Based Maintenance Management Framework is given below.