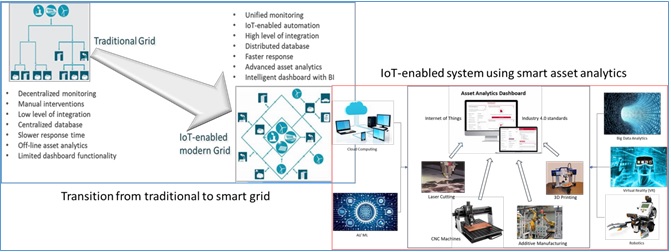

The traditional asset management system practiced in Utilities and Industries is now moving towards ‘real-time’ solutions. While traditional asset management system does provide vital asset information and asset behaviour during operations, the information is available post-factor. This means that the traditional system provides information for course correction in the future based on historical data, however, it cannot do anything about the lost opportunity or the events that has already taken place with whatever impact they may have on the assets.

On the contrary, a ‘real-time’ asset management system with intelligent analytics, captures and processes data in real time, monitor asset trends in real time and perform data modelling, which can provide important insights to correct any anomaly in the asset or network behaviour on the fly. This saves valuable time, money, efforts and risks in system or asset restoration.

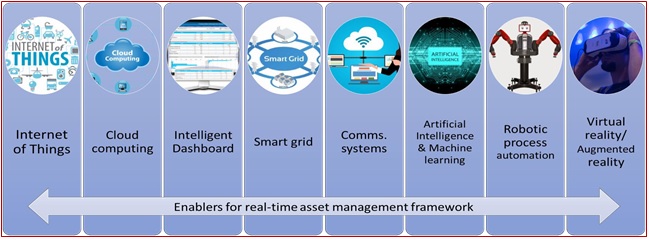

The enabling technologies for the implementation of ‘real-time’ asset management system framework with advanced asset analytics are the following:

The business benefits of various technologies are summarized below:

| Technology use case | Technology Drivers | Business benefits |

|---|---|---|

| Failure prediction of MV feeders. | IoT systems, smart communications and intelligent dashboard. | Improving asset reliability and reducing asset risk exposures, ability to do the root cause analysis to prevent future failures. |

| Failure prediction of MV Switchgear and Transformers. | IoT systems, Cloud computing, AI/ ML, VR/ AR and Smart grid technologies | Reliable and real-time asset condition data monitoring including operational data to improve network reliability and reduce cost of maintenance though predictive analytics. |

| Short-term and Long- term load forecasting | IoT systems, smart grids communication, AI/ ML and intelligent dashboard | Load forecasting & modelling can help correlate load growth, time-of-use, demand projections, customer behaviors and weather variations, during CAPEX planning. |

| Lifecycle or TCO prediction | Intelligent visualization, smart grid analytics, IoT- based systems and AI/ ML | TCO is influenced by condition-based maintenance and predictive maintenance, which can reduce maintenance costs, improve asset life and reduce asset carbon footprints. |

| Probability of failure modelling | Smart grid analytics, Intelligent visualization dashboard | Both CAPEX and OPEX reduction can be achieved using Probability analysis and modelling, integrating key asset variables and historical data. |

| Asset health, risk and criticality modelling | IoT systems, Cloud infrastructure, AI/ ML and smart grids | Asset health and risk analysis using relevant condition-based data to reduce TCO and increase asset life span. |

| Full substation load and performance monitoring of MV/ LV substations | Smart grid analytics, IoT systems, intelligent dashboard, SCADA/ DCS and GIS-based systems | PPU substations are critical to Distribution System which should be monitored for greater network visibility and situational awareness. Status information of critical substation assets can reduce cost of maintenance and compliance. |

| Transformer and Switchgear dynamic or real-time health monitoring capability | IoT systems, smart grids and communications,intelligent dashboard | Transformer and Switchgear at PMUs can be monitored, simulated for dynamic rating assessment, optimal loading and asset utilization, leading to cost optimization. |

| MV underground cables, end of life assessment & cable dynamic loading based on health monitoring. | IoT systems, Smart grid and communications, intelligent dashboard and AI/ ML | MV underground cables can be fully assessed in terms of loading capacity, dynamic loading for enhanced asset utilization and optimal investments in new network capacity. Increases asset life span and reduces costly replacements. |